Quality Assurance

All MINZ Energy Systems are made, assembled, and QC in Taiwan to ensure best

quality. We conduct 100% inspection on all spare parts and make sure each system meets your machine‘s required pressure curve before delivery, following ISO 9001 standards.

Additional Benefits

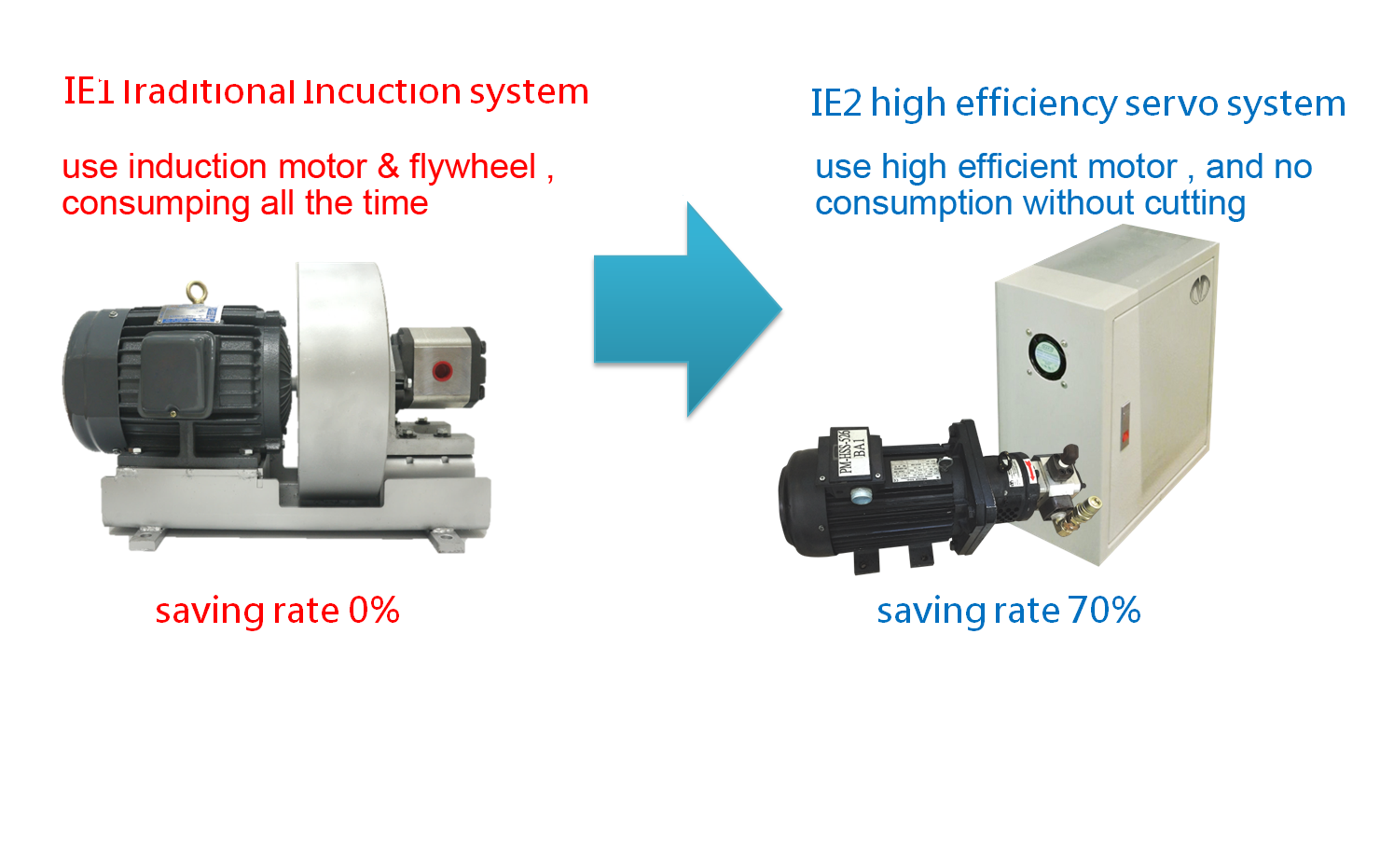

Besides electricity saving after installing MINZ Energy System, your machine’s motor and hydraulic fluid temperature are decreased to room temperature, greatly improved your working environment. Chiller can also be turned off to save additional electricity consumption. Hydraulic fluid’s lifetime is doubled as well.

Furthermore, servo system’s precise injection can help reducing production defects and generation of material wastage.

Fast ROI

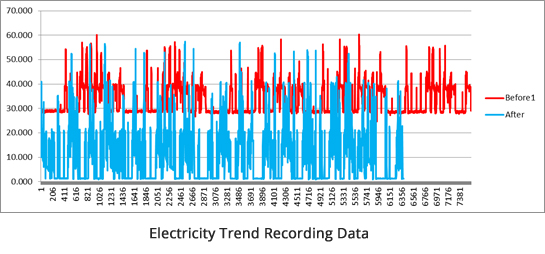

Take EVA Injection Machine with MINZ Energy System installed for example, averagely 23 kwh is saved each hour, which is equivalent to US$ 22,000 electricity savings per year. Not only does this help you lowering down production cost, but also lowers CO² generated for kwh, giving our next generation a better environment.

*Red indicates the original power system, blue indicates MINZ Energy System

MINZ Honor

MINZ engineering team has travelled to 20 countries around the globe to save energy for industrial machinery. In 2012, we helped the world save more than 1.7 million kwh, and was awarded The Best CSR and Green R&D Awards by Taiwanese Vice President Mr. Wu.

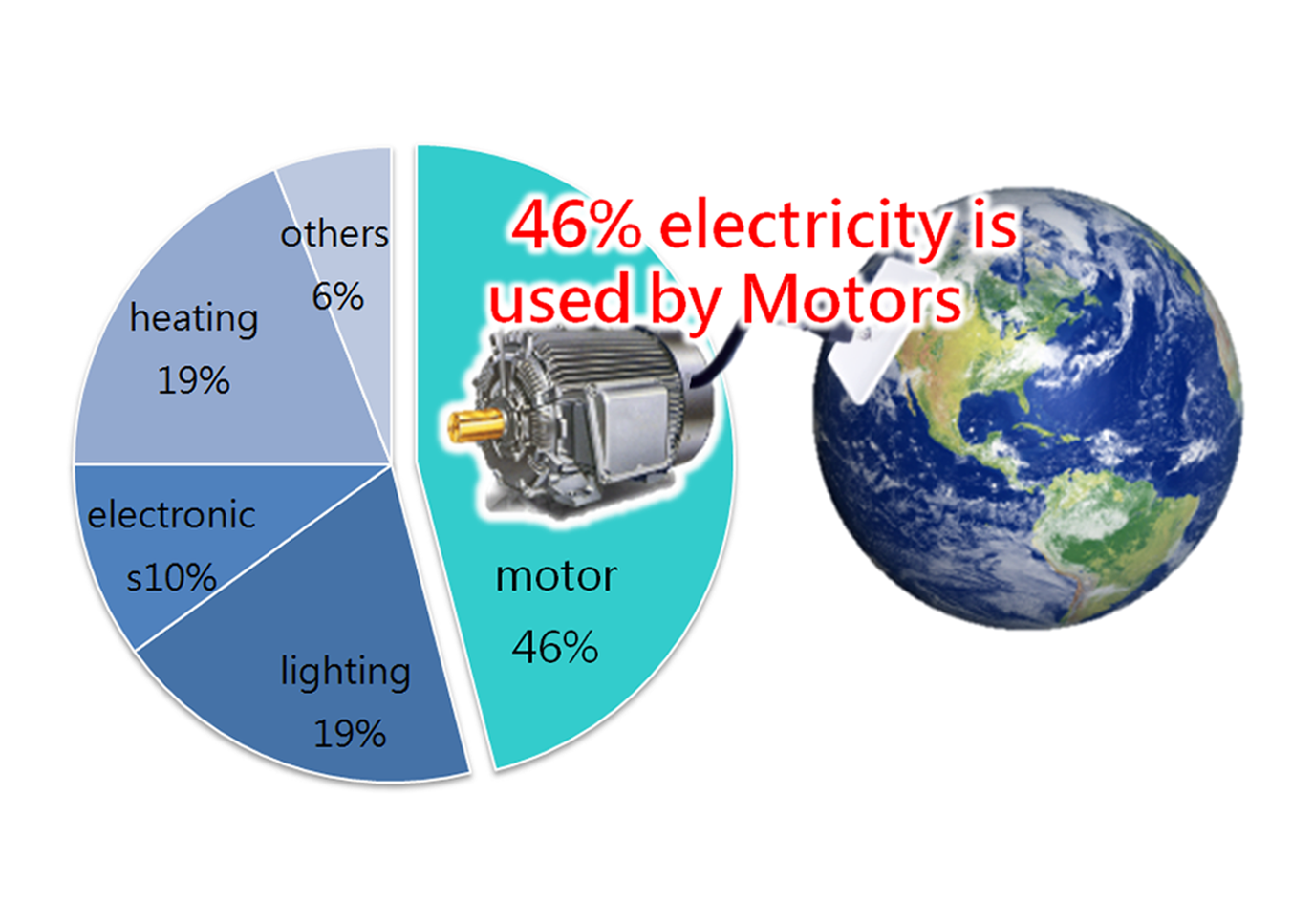

We cannot influence the raising speed of global material price, but we can assist you in lowering your production’s energy consumption and wasted material. 1 kwh of electricity generates 0.636 kg of CO²; however, a tree can only absorb 456 kg of CO² a year. Take Dah-An Park - Taiwan's largest park for example, it contains 20,745 trees. So far, MINZ’s clients have assisted the world planting grown-up trees equivalent to 16 Dah-Ah Parks. Our goal is to build 200 more Dah-An Park in the next decade with you!!

CO² deduction is every country’s responsibility. Let’s act now!